Kverneland iXdrive S6

Qualité, productivité et performance !

La gamme Kverneland iXdrive S6 se compose de l'iXdrive HP (High Performance) comme modèle de base et de l'iXdrive HP ECODRIVE comme modèle haut de gamme, avec des caractéristiques telles que le moteur Power Tech Stage V, la commutation individuelle des bouchons iXflow-E et le système de gestion des fluides iXclean Pro. Kverneland propose une gamme de pulvérisateurs adaptée aux agriculteurs et aux entrepreneurs.

Description

L'iXdrive S6 est disponible jusqu'à une capacité nominale de 6150 litres en combinaison avec deux types de rampes différentes : la rampe en aluminium HSA (24-30m) et la rampe en acier HSS (24-40m). Le système de guidage de la rampe assure un équilibrage parfait de la rampe, pour une pulvérisation très précise. La suspension hydropneumatique unique sur les deux essieux assure le confort de l'opérateur et la stabilité de la rampe pendant le transport et sur le terrain. Le panneau de commande EasySet offre un poste de travail propre et pratique, avec tous les composants nécessaires à portée de main. La technologie de pulvérisation est facilement contrôlée depuis la cabine grâce au terminal Tellus PRO d'IsoMatch, au joystick Grip d'IsoMatch et au logiciel innovant iXspray doté d'une interface tactile intuitive. Contrôlez votre flotte, gérez les tâches à distance ou analysez les données de performance de la machine avec IsoMatch FarmCentre.

Points forts

- Le panneau de commande EasySet offre un espace de travail propre et pratique avec tous les composants nécessaires à portée de main.

- iXspray est une interface utilisateur intuitive et des commandes conviviales qui garantissent que la pulvérisation est effectuée de la manière la plus simple et la plus efficace.

- Excellent confort de conduite.

- iXclean Pro - système de gestion de la grue entièrement automatique depuis la cabine haut de gamme.

- iXflow-E - système de recirculation à haute pression avec commutation électrique individuelle des bouchons pour améliorer la qualité de la récolte et réduire les coûts.

- Le parallélogramme allie stabilité, équilibre et limitation des mouvements verticaux pour minimiser les écarts de hauteur de pulvérisation.

- IsoMatch FarmCentre est applicable aux machines Kvernel et ISOBUS - reliant les outils et les terminaux en un flux continu de données et de connectivité.

Caractéristiques

HSS 24-27-28-30-32-33-34-36-38-39-40m Compact Side Folding Steel Booms

- The special HSS profile combines a minimum of weight with maximum strength and stability. The HSS boom range is designed for professional use. It's triangular construction provides perfect integration of the stainless steel spray lines, nozzles and nozzle holders and the optimal hose routing where all is well protected. The HSS boom range consists out of a range of two-part folding (24-30m) and three-part folding (32-40m) spray booms. HSS 32-40m 2nd generation boom is designed for higher capacity, higher working speed and higher demands.

HSA 24-27-28-30m High Tech Side Folding Aluminium Booms

- The high tech HSA aluminium spray boom efficiently protects the nozzle holders within the bottom profile of the boom. This profile is designed for easy cleaning with no sharp angles or corners for residue and liquid to collect. The anodised surface protects against corrosion and scratches.

iXflow-E

- The HSS and HSA spray booms are equipped as standard with iXflow-E. iXflow-E is the high pressure recirculation system with electric nozzle control. There is a free circulation of chemicals with a return of spray liquid back to the tank when spraying stops. This means there is no sedimentation in the spray lines and no dead ends for spraying or cleaning. During spraying each section gets under pressure from both ends of the spray lines, so the operator can immediately start spraying without any pressure drop. It is easy for the operator to program the number and size of sections which fits the best to their requirements and field situations.

Boom Guide Pro

- This advanced system uses three ultrasonic sensors to control left- an right-hand boom sections independently for the ultimate guidance in the most challenging field conditions. It can deliver positive and negative lateral movement on each side of the boom to follow the contours in every situation!

Boom Guide ProActive

- The system proactively reacts on boom movement and controls both the central and independent slope correction, as well as boom lift functions to guide the boom over the crop canopy, soil surface or a combination of both modes.

Boom Guide 5 Sensor Extension

- The Boom Guide 5 sensor extension provides two additional ultrasonic sensors to ensure proper height measurements with booms reduced to 24 metres working width by folding the tip-ends.

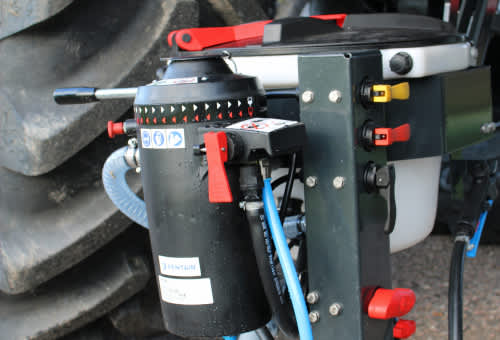

EasySet control panel.

- The EasySet control panel is located between the wheels, at the left hand side of the iXdrive. The panel is redesigned to create a clean and convenient workspace with easy access to all the connections and filters. The control panel is well protected with a bottom cover to keep your operational area free of dirt and chemicals. It is equiped with a Focus3 colour terminal for valve operation and an operating panel for engine and hydraulic functions. The chemical inductor has a new compact design and is hydraulically folding. Furthermore, can be equipped with a Closed Transfer System, which will be obligatory in Europe in short term.

iXclean Pro

- The iXdrive is equipped as standard with iXclean Pro our fully automatic electric valve management system. It means all functions can be controlled from the cab or the control panel. Switching between filling, agitation, spraying, diluting, priming, rinsing and tank cleaning is extremely easy: just push the button! iXclean Pro also offers a fully automatic multi-step rinsing and cleaning program again with the push of one button! It just takes a few minutes and residue levels are after automated cleaning below 1%.

Pump with unique service position

- The 520l/min piston-membrane pump of the iXdrive is positioned on the right side directly under the main tank resulting in the smallest hose lengths possible. Unique is the service position of the spray pump. The pump is mounted on a rail to be able to easily slid out or to take out completely for maintance purposes.

iXspray

- The innovative iXspray spray computer program is operated by the IsoMatch Tellus Pro ISOBUS terminal in combination with IsoMatch Grip joystick. iXspray guarantees an user friendly operation of the sprayer. iXspray is full of nice features to make the operators life easy, save time and avoid mistakes in a busy working season, for example pre-sets for spray jobs and boom configuration can be configured easily.

Wheel Axles

- The hydro pneumatic suspension on both axles provides operator comfort and boom stability both in transport and field operation. The 3D rear axle suspension allows axle movement, but limits the track influence on the spray boom. The strong chassis with an optimal gravity point brings a perfect 50%-50% weight balance in every situation, without any influence from tank filling or spray boom position. Manoeuvrability is guaranteed with 2-wheel, 4-wheel and crab steering modes as well as ErgoDrive headland control management as standard.

Adjustable Track Width

- For optimal protection of the crop the iXdrive S6 is available in three different ground clearances: 1.30m, 1.50m and 1.70m. The trackwidth for the 1.30m clearance frame is 1.80 - 2.25m. Both other clearances come with a track width of 2.25 - 2.95m both offering maximum stability and row spacing in different crops.

- Track width adjustment with hydraulic support is standard feature on the iXdrive. Optional is a hydraulic operation from the cab adding more comfort and flexibility.

The HP-ECODRIVE model is the top level offering automatic engine RPM which means maximal control.

The HP-ECODRIVE model is the top level drive line with standard 300hp stage V engine resulting in a super comfortable 1350 RPM engine at 40km/h road transport. With HP-ECODRIVE the engine RPM will automatically decrease when possible and increase when necessary. This obvious fuel savings result in maximum cost efficiency and comfort for the driver.

Easy Operation

- The HP-ECODRIVE model has a similar field operation as the HP model. During road transport the manual joystick only selects the driving direction. The driving pedal determines the speed and acceleration, whereas the brake pedal is operated when slowing down. The benefit is a very relaxed road transport operation, like a car with automatic gearbox or even better a continuously variable gear box.

Continuous 4-wheel drive

- The iXdrive has a smart hydraulic layout which guarantees a permanent 4-wheel drive. The hydraulic drive line is fed by 2 hydraulic pumps: one for the front axle and one for the rear axle. The oil flow for one axle can not go to one wheel only, resulting in a permanent traction on all 4 wheels. This is always standard equipment and is always activated. Comfortable for the driver: he cannot forget to activate the 4-wheel drive and he will not get stuck accidentally.

Reliable wheel motors

- The HP wheel motors are optimised on all levels. Most important is the efficiency, where the motors can supply higher power especially at low speed, they still consume less power, which is even more reduced at higher speeds. This efficiency saves fuel and is in the meantime more efficient with the available power. In combination with the HP-ECODRIVE technology the user experiences a step less speed variation providing power when it is needed and reducing engine RPM’s when possible.

Integrated brakes

- The active brakes are integrated in the wheel motors. The HP-ECODRIVE model has integrated brakes on all 4 wheels.

The iXdrive S6 is equipped as standard with a HP (High Performance) drive line. The sophisticated hydraulic setup results in a more efficient use of the available power.

The standard HP model has a 250hp diesel engine and a hydraulic drive line set up for maximum and efficient use of the available power. The hydraulic system provides a step less speed variation reducing engine RPM when possible resulting in optimal efficiency and comfort. The engine is a John Deere 6 cylinder 250hp single turbo with European Stage V emission as standard. Optional available are a 250hp Tier 2 and 300hp Stage V engine.

Easy Operation

- The HP model is always operated by the manual joystick. This intuitive operation comforts the driver very quickly during field operation as well as during road transport. The brakes are activated by the brake pedal.

Continuous 4-wheel drive

- The iXdrive has a smart hydraulic layout which guarantees a permanent 4-wheel drive. The hydraulic drive line is fed by 2 hydraulic pumps: one for the front axle and one for the rear axle. The oil flow for one axle can not go to one wheel only, resulting in a permanent traction on all 4 wheels. This is always standard equipment and is always activated. Comfortable for the driver: he cannot forget to activate the 4-wheel drive and he will not get stuck accidentally.

Reliable wheel motors

- The HP wheel motors are optimised on all levels. Most important is the efficiency, where the motors can supply higher power especially at low speed, they still consume less power, which is even more reduced at higher speeds. This efficiency saves fuel and is in the meantime more efficient with the available power.

Integrated brakes

- The active brakes are integrated in the wheel motors. For the HP model only the front axle is equipped with active brakes.

La gamme complète de rampes Kverneland HSS en acier est disponible de série avec un espacement entre buses de 50 cm. Des porte-buses supplémentaires peuvent être ajoutées à la rampe pour obtenir un espacement entre les buses de 25 cm.

Meilleure couverture des cultures et réduction de la dérive

Les buses à 25 cm permettent de réduire la dérive et d’augmenter la couverture du traitement grâce à une pulvérisation plus proche de la cible, à 30 cm de hauteur, tout en gardant une répartition homogène de la bouillie avec des gouttelettes de taille optimale.

Augmentation de la fenêtre de pulvérisation

Le passage facile de 50 à 25 cm de distance entre les buses vous permet plus de flexibilité pendant la pulvérisation et permet de disposer de plus de temps pour pulvériser dans des conditions optimales en diminuant l’impact des conditions météorologiques.

La distance entre buses de 25 cm est disponible en option en plus de l’espacement standard de 50 cm avec l’ensemble des circulations (sections centrales, circulation continue iXflow-Air et circulation continue iXflow-E). Cette option peut être installée ultérieurement.

Caractéristiques techniques

Caractéristiques techniques

Télécharger la documentation| iXdrive S6 | ||||

|---|---|---|---|---|

| Nominal tank volume (l) | 4250 | 5200 | 6150 | |

| Maximum tank volume (l) | 4500 | 5500 | 6500 | |

| Chemical inductor (l) | 30 | 30 | 30 | |

| Clean water tank (l) | 520 | 520 | 520 | |

| Hand wash tank (l) | 15 | 15 | 15 | |

| Spray boom (m) | HSA 24-30/HSS 24-40/30-24/36-24 | HSA 24-30/HSS 24-40/30-24/36-24 | HSA 24-30/HSS 24-40/30-24/36-24 | |

| Pumps (l/min) | 520 | 520 | 520 | |

| iXclean | iXclean Pro | iXclean Pro | iXclean Pro | |

| Controls for ISOBUS Electronics | IsoMatch Tellus PRO/GO+ | IsoMatch Tellus PRO/GO+ | IsoMatch Tellus PRO/GO+ | |

| Ground clearance (m) | 1.30/1.50/1.70 | 1.30/1.50/1.70 | 1.30/1.50 | |

| Track width - hydraulic adjustable (m) | 1.30 = 1.80-2.25/1.50-1.70 = 2.25-2.95 | 1.30 = 1.80-2.25/1.50-1.70 = 2.25-2.95 | 1.30 = 1.80-2.25/1.50= 2.25-2.95m |

Caractéristiques techniques

Caractéristiques techniques

Télécharger la documentationiXdrive S6 |

|||

Nominal tank capacity (l) |

4.250 |

5.200 |

6150 |

Maximum tank capacity (l) |

4.500 |

5.500 |

6.500 |

Clean water tank (l) |

520 |

||

Ground clearance (m) |

1.30 / 1.50 / 1.70 |

1.30 / 1.50 |

|

Track width (m) |

1.80 - 2.25 / 2.25 - 2.95 |

||

Spray booms (m) |

HSA 24-30 (2 part folding) / HSS 24-30 (2 part folding) / HSS 32-40 (3 part folding |

||

Diesel engine |

John Deere PowerTech 250 HP Stage V optional 300 HP Stage V or 250HP Stage II |

||

iXclean Pro, iXflow-E |

Standard |

||