Rotago F

Outils de travail du sol | Herse rotative

Les herses rotatives Kverneland sont une combinaison remarquable d'innovation et de puissance, ouvrant ainsi de nouvelles perspectives pour l'avenir de l'agriculture !

La herse rotative Kverneland Rotago F est une herse rotative pour les travaux intensifs, conçue pour des tracteurs d'une puissance allant jusqu'à 400 ch en combiné de semis.

Points forts

- Perfectly levelled and even seedbed

- Patented depth adjustment on the go

- ISOBUS for full and easy control

- Maximum resistance against radial stress

- Robust gear case and transmission

Description

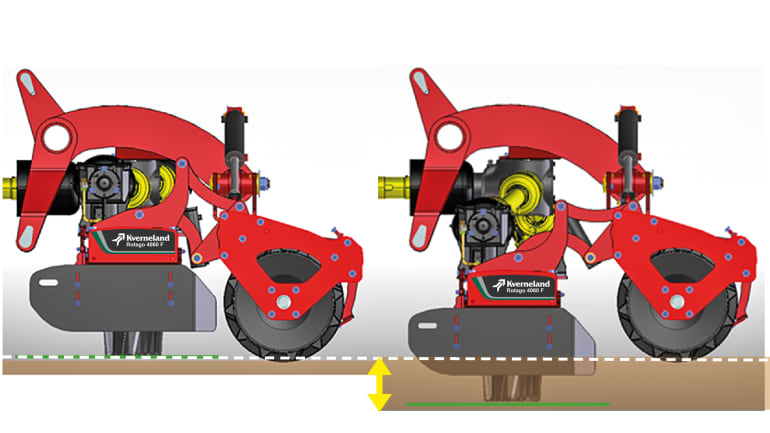

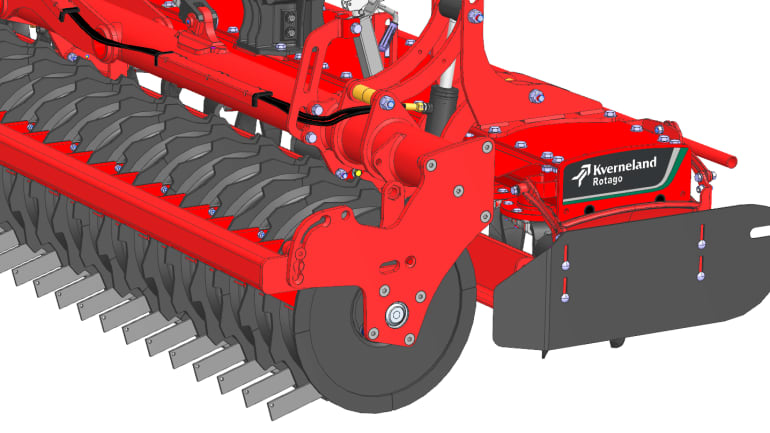

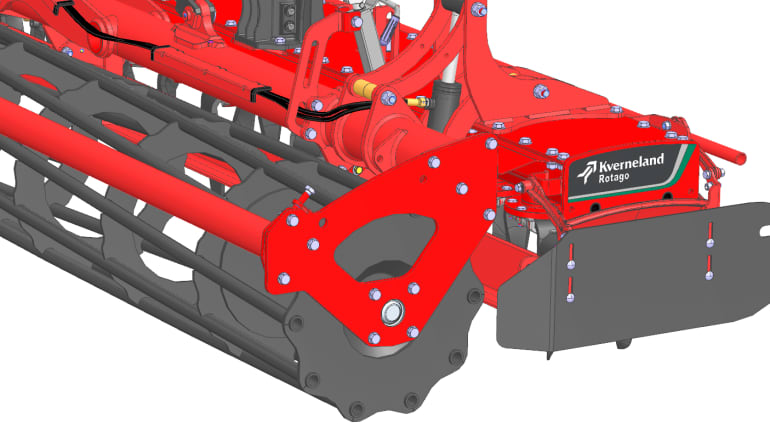

La herse rotative repliable Kverneland Rotago 4000 F est disponible dans des largeurs de travail de 4 m, 4,50 m, 5 m et 6 m. Pour le transport sur route, elle se replie en toute sécurité dans une largeur de 3 m. Avec ses quatre rotors par mètre, elle offre une qualité d'émiettement optimale, avec une durabilité maximale pour préparer les sols année après année. Sa conception est unique sur le marché : l'attelage est solidaire du rouleau et constitue ainsi le point de référence pour le réglage de la profondeur et de la qualité d'émiettement. Grâce à la compacité de la tête d'attelage et à la connexion directe du rouleau, le centre de gravité est très proche du tracteur. Depuis la cabine, vous pouvez ajuster hydrauliquement la hauteur de travail de la herse et de la barre niveleuse avec précision. La Kverneland Rotago est prête à évoluer dans tous les types de sols et toutes les conditions grâce à un large choix de dents et de rouleaux. En plus du travail en solo, la Rotago F peut recevoir une barre de semis repliable Kverneland f-drill pour réaliser un combiné de semis avec trémie frontale.

Points forts

- Qualité d'émiettement supérieur

- Concept unique d'attelage solidaire du rouleau pour un réglage précis de la profondeur

- L'intégralité des réglages depuis la cabine

- Résistante pour une durée de vie maximale

- Intensité de travail facilement réglable en cours de chantier

- Prêt pour toutes les conditions grâce à un choix complet de dents et de rouleaux

- Combinaison possible avec une trémie frontale et une barre de semis f-drill

Caractéristiques

Caractéristiques

An efficient seedbed preparation is needed for an even seed emergence and strong plant development. The Rotago F, power harrow, prepares an optimal seedbed with a load-bearing seed horizon in which the seed can be placed at an even depth over the entire working width. The constant depth control avoids unnecessarily deep cultivation. The Rotago F leaves fine soil in the sowing horizon and coarser crumble structure at the surface for a weatherproof finish. A seedbed which allows also a rapid warming up of the soil and an adequate oxygen supply of the seeds. Deep tracks and compacted zones in the ground are removed. The Rotago F establishes an unbroken connection between the seed horizon and the capillary water conducting lower layer to ensure germination in the absence of rainfall.

The Kverneland ROTAGO F power harrow is available in two models, as basic and as ISOBUS edition. Both versions offer levelling bar and working depth adjustment on the go. As basic version the working depth is adjusted by the tractor hydraulics and as ISOBUS model more comfortable via the tractor or Kverneland terminals Tellus Pro/Tellus GO+ on the go from cab. It is up to the farmers’ experience and knowledge where the soil needs more or less intensive preparation. One button press on terminal or tractor hydraulic and the setting is done. The Rotago F is ready for all future farming concepts and challenges.

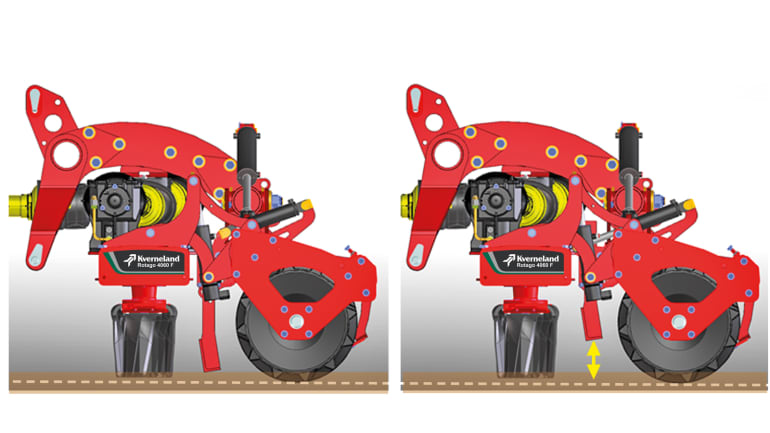

The patented ROTAGO concept with the pushed gear case allows the depth adjustment without any changes on the 3-point linkage or the rear roller. The parallelogram linkage ensures that the gear case stays always parallel to the ground. The levelling bar is fixed to the roller frame and can be adjusted as well from the cab.

The main frame is directly linked to the rear roller. This ensures that the pivoting point and the main frame are in the center of gravity. The pushed gear case is independent of the frame and totally independent of all the other components of the machine, which reduces the stress and protects from additional forces.

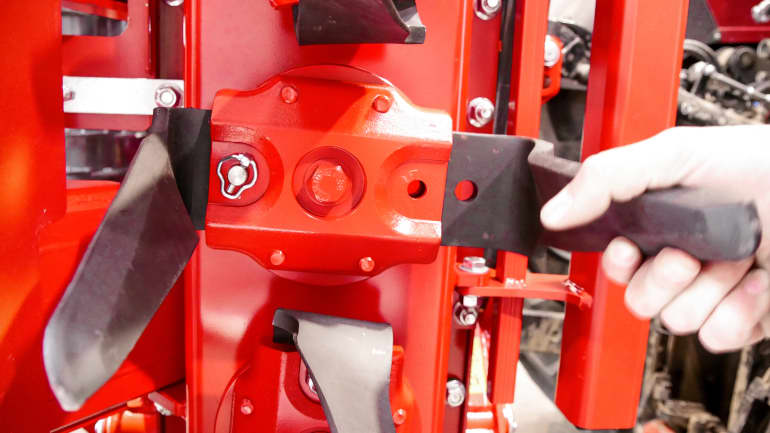

The Rotago F is equipped with Quick-Fit tines as standard. These are secured by a special pin and clip mounted in the tine holder. Tine replacement is, therefore, very easy without the need for tools. Downtime can be further minimized by an optional carbide layering of the tines. This will ensure a long liftime and minimum wearing even in tough and abrasive soils. Depending on soil conditions there is the choice of Standard, Active tines and XHD tines.

Active tines

The active tines ensure optimum penetration in hard or not cultivated soil. The tine, due to its shape, pulls itself into the ground. This gives a constant working depth and also prevents the machine from lifting out of the ground in hard dry soil conditions. In addition, it creates additional re-compaction at the packer roller. The active tine lifts the material and pushes it in front of the power harrow. This gives an optimum levelling effect even in tractor tracks. In mulch conditions the active tines can work directly into stubble and hard soil. The special shape of the tines keeps residues on the surface and this gives a big advantage against erosion.

XHD tine

The XHD Carbide reinforced tines are protected against extremely abrasive soil conditions. These tines are designed to offer you longer lifetime, keeping costs and downtime to a minimum in environments where standard tines are wearing too fast.

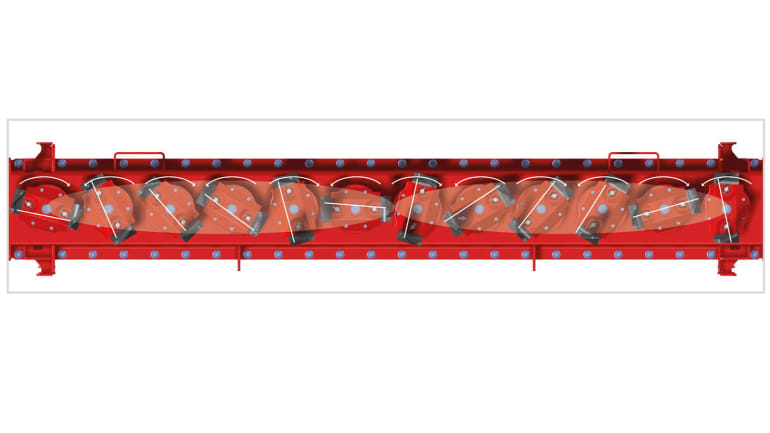

Helical tine positioning

The tines are arranged in varying angle positions in order to prevent damage caused by stones and ensure even levelling. 4 rotors per meter and the helical tine positioning reduce the peak loads on the driveline which results in smoother running and less fuel consumption. All gears are hardened in the trough for a long lifetime.

Re-consolidation for a stable soil structure with the right roller for all types of soil and conditions

Rollers ensure re-compaction of the soil as final step of the optimum seedbed preparation. By reducing soil porosity and limiting evaporation, all plants will have the same access to nutrients, moisture and light. This will give the crop a good start for a perfect growth and high yields.

Actipack ø560mm – 205 kg/m

- For medium to heavy soils, also in wet, stony and sticky conditions due to the independent skids and knives

- The cutting discs break the larger clods whilst the adjustable knives cut the remaining clods resulting in optimal clod breakdown and fine seedbed preparation

Actiline Roller ø550mm – 185 kg/m

- For light to medium and heavy soils

- Trapezoidal roller with relatively narrow crest width of 40mm

- Stripe-wise consolidation and V shape furrow in front of the CX-II seed coulter bar

- Supporting water holding capacity and oxygen exchange

- Good carrying capacity with full self-cleaning effect

- Crests support the constant drive of the roller and avoid slip in light or tough and wet conditions

- Two different ring distances of 12.5cm and 15cm

- Carbide-coated scrapers on request

Tooth Packer roller ø575mm – 160kg/m

- For medium to heavy soils, also in wet, stony and sticky conditions due to the independent skids and knives

- The cutting discs break the larger clods whilst the adjustable knives cut the remaining clods resulting in optimal clod breakdown and fine seedbed preparation

Cage roller ø550mm – 90kg/m

- Light to medium soil and dry working conditions e.g. seed bed preparation for potato planting

- 10 bars for a good loading capacity and option in wet conditions

In conventional tillage systems, once the working depth is set, it is maintained over the entire field. However, the depth of compaction and the availability of soil moisture may vary greatly. Changing soil conditions require different implement adjustments. With the Rotago F, all relevant functions can be steered from cab by using only one DA valve. One button press on the terminal and the setting is done. The driver has all settings at one glance and can monitor the functions and the gear box temperature.

Functions steered by the terminal:

- Folding, unfolding and transport wheel (option)

- Working depth of power harrow and levelling bar

- Sowing depth and coulter pressure

- Track marker arms (also in solo operation)

- Compatible with all ISOBUS terminals.

IsoMatch Tellus PRO

The IsoMatch Tellus PRO 12-inch terminal provides you with the optimal solution for an all-in-one control system inside the tractor cab. It is the centre for connecting all ISOBUS machines, running precision farming applications and Farm Management Systems. It offers everything you need to get the maximum out of your machines and crop, as well as cost savings in fertiliser, chemicals and seeds by using automatic section control and variable rate control. With the unique dual screen functionality, it gives you the opportunity to view and manage two machines and/or processes simultaneously.

IsoMatch Tellus Go+

The IsoMatch Tellus GO+ is a cost efficient 7-inch terminal, especially developed for managing the machine in a simple way. Easily set up the machine with the soft keys and simply use the hard keys and rotary switch for optimal control whilst driving.

The Kverneland Rotago F is quickly and easily folded from working to transport position, max. 3.00m, from the tractor cab. For a better load balance, extra stability and legal road transport, an extra support wheel is available which can be mounted at the power harrow or coulter bar.

No uncoupling of the top linkage is needed. The constant hydraulic supporting force on the wheel ensures smooth running and increases driver’s safety and comfort. The Rotago F models with support wheel are homologated (in Europe) for 40km/h.

A LED road light kit is optionally available for the Rotago F.

Caractéristiques techniques

Caractéristiques techniques

Télécharger la documentation| Données techniques | Rotago 4040 F | Rotago 4045 F | Rotago 4050 F | Rotago 4060 F | |

|---|---|---|---|---|---|

| Largeur de travail (m) | 4.00 | 4.50 | 5.00 | 6.00 | |

| Largeur de transport (m) | 3.00 | 3.00 | 3.00 | 3.00 | |

| Vitesse d'entrée de la prise de force (tr/min) | 1000 | 1000 | 1000 | 1000 | |

| Vitesse des rotors (tr/min) | 344 et 455 | 344 et 455 | 344 et 455 | 344 et 455 | |

| Puissance minimale requise | 130 | 140 | 160 | 180 | |

| Puissance maximale autorisée en combiné de semis | 400* | 400* | 400* | 400* | |

| Protection contre la surcharge du boîtier d'entraînement (Nm) | 2000 (par embrayage automatique à entraînement latéral) | 2000 (par embrayage automatique d'entraînement latéral) | 2000 (par embrayage automatique d'entraînement latéral) | 2000 (par embrayage automatique d'entraînement latéral) | |

| Nombre de rotors / Nombre de dents | 16 / 32 | 18 / 36 | 20 / 40 | 24 / 48 | |

| Dimension des dents (mm) | 15 x 330 | 15 x 330 | 15 x 330 | 15 x 330 | |

| Type de dents | Montage rapide en standard | Montage rapide de série | Adaptation rapide de série | Adaptation rapide de série | |

| Poids avec barre niveleuse, rouleau packer et cardan (kg) | 2800 | 2950 | 3150 | 3550 | |

| Poids avec barre niveleuse, rouleau packer, cardan et roue de transport (kg) | - | - | 3400 | 3800 | |

| Réglage de la profondeur de travail | Hydraulique en cabine | Hydraulique en cabine | Hydraulique en cabine | Hydraulique en cabine |

*seulement en combinaison avec une barre de semis

Caractéristiques techniques

Caractéristiques techniques

Télécharger la documentationModel |

Rotago F |

Frame |

Fold |

Working width (m) |

4.0 - 4.5 - 5.0 - 6.0 |

No. of rotors |

16 - 18 - 20 - 24 |

Rotor clearance (mm) |

95 |

Tine dimension (mm) |

15 x 330 |

Min. to max. (HP) |

130 x 360 |

Rear rollers |

Cage roller, Tooth Packer roller, Actipack roller, Actiline roller |

*seulement en combinaison avec une barre de semis