Kverneland Satio F

Semoirs | Semoir pneumatique solo

Semoir solo grandes largeurs - débit de chantier et flexibilité pour les semis

Semoir compact Kverneland Satio F pour travailler en solo avec des tracteurs de petite et moyenne puissance

Points forts

- Compact & lighweight design - low power requirement

- Flexible - sowing independently from seedbed preparation

- Precise seed placement

- Cost-efficient

- High sowing speeds - large performance

Description

Le semoir compact solo Kverneland Satio F est disponible en largeur de travail de 5 et 6 m. Le Kverneland Satio F offre une flexibilité supplémentaire pour s'adapter au changement climatique en venant dissocier la préparation du lit de semences et le semis. La puissance requise est faible grâce à un centre de gravité proche du tracteur. Les vitesses de semis plus élevées permettent d'exploiter au mieux les fenêtres météorologiques disponibles pour les semis. La trémie de semence offre une grande capacité de 1 700 litres. Le doseur à entraînement électrique ELDOS (1-400 kg/ha) est disponible en version e-com ISOBUS, ou en e-bas entrée de gamme, et offre un maximum de confort. Un radar de vitesse permet d'apporter la densité hectare souhaitée.

L'élément semeur CX-II, avec ou sans roues plombeuses, est bridé sur la barre de semis pour adapter l'écartement en fonction des protocoles de semis, pour par exemple intégrer du désherbage mécanique. La pression d'enterrage des éléments semeurs est réglée mécaniquement, ou peut être contrôlée hydrauliquement depuis la cabine. La profondeur de semis est centralisée avec un système de cales. Les roues plombeuses permettent d'optimiser le contact terre-graine et obtenir des germinations plus rapides et homogènes. Elles peuvent être minorées. Les efface-traces intégrés sont de série

Une gamme complète d'options telles que les traceurs de pré-levée, la herse de recouvrement à dents en S ou les feux de travail à LED sont disponibles pour s'adapter aux besoins individuels.

Points forts

- Conception compacte et légère - Faible consommation de GNR

- Flexibilité - semis indépendant de la préparation du lit de semences

- Dosage précis des semences - doseur électrique ELDOS

- Placement précis de la semence - élément semeur CX-II avec ou sans roues plombeuses

- Rentabilité grâce à son débit de chantier important

- Haute performance - vitesses de semis plus rapides, grande capacité de trémie

- Contrôlé par l'ISOBUS

Caractéristiques

Caractéristiques

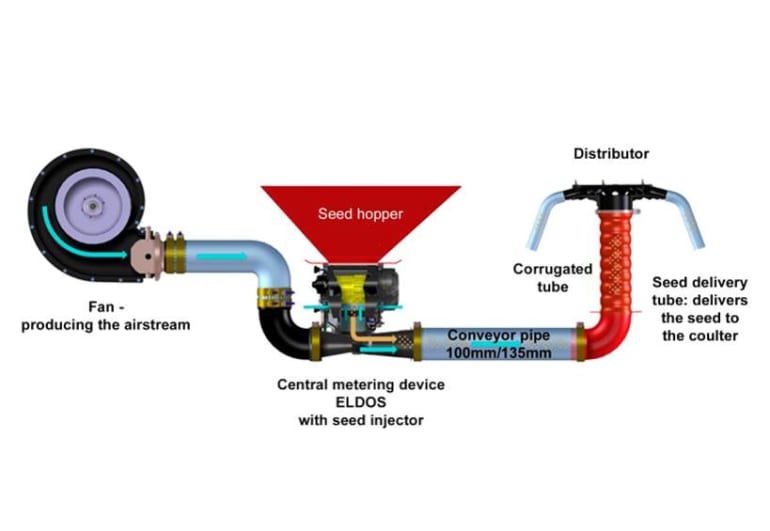

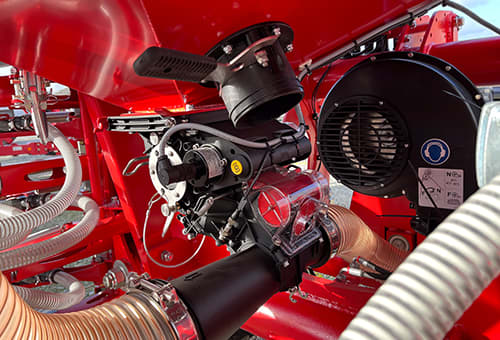

- The metering device ELDOS accurately measures the required volume of seed by the distinctive rotor and discharges it into the seed injector where is is mixed with the air stream and then conveyed through the diffusor tube and the seed delivery hoses to the coulters.

- The distribution head is mounted in a protected position inside the seed hopper.

- ELDOS is electric driven by e-bas and e-com, the e-com edition is fully ISOBUS compatible, e-bas works as stand alone controlled system.

- GEOCONTROL by GPS signal is possible which avoids double seeding.

- Special sensors ensure functionality from the tractor cab.

- Five standard rotors are delivered: for fine and large seeds or fertiliser.

- The exchange of the rotors is quickly and easily done without any tools.

- Application rates from 1 to 400kg/ha are possible (depending on working speed and width).

- The metering device is always easily accessible.

Calibration

- Very simple calibration test due to the separate seed guidance.

- A remote control allows the driver to operate the calibration process at the metering device.

- No gear has to be adjusted. The driver simply enters the desired values into the terminal, presses one button to start at the metering device and that’s it.

- The calibration is done automatically.

- A calibration flap with an integrated gate prevents any seed from dropping into the hose.

- The CX-II disc coulter from Kverneland not only guarantees smoother running but also exact seed placement.

- The flatter cutting angle of only 5.4° of the steel disc requires less pulling power to reach a constant seeding depth of up to 6cm.

- Due to the combination of the steel disc with a diameter of 325mm and the flexible plastic disc, there is no need for independent scrapers, saving the cost for expensive wearing parts. In addition the coulter is completely maintenance-free!

- Up to 50kg coulter pressure can be achieved by a pre-loaded spring. Safe operation is ensured when working with high working speeds and high quantities of plant residues on the soil surface.

- An inter-row coulter spacing of 445mm for maximum clearance and the following press wheel (standard equipment) ensure an optimum seed/soil contact in all conditions.

- The press wheels can be set in fixed, floating of lifted position in order to be able to adapt quickly to changing weather, soil or working conditions.

- The CX-II coulter is also available as light edition without press wheel which reduces the weight and length of the coulterbar. This will allow to operate the seeding combination also with lower lifting capacity of the tractor.

The Satio F is available as e-bas and e-com model. Both models are equipped with the electric ELDOS metering device. The Satio F e-bas is not ISOBUS compatible and the electronic control is ensured by the Focus 3 terminal. The Satio F e-com model on the other hand is fully ISOBUS controlled and can be steered by the Kverneland IsoMatch Tellus GO+, the IsoMatch Tellus PRO or any other terminal.

Focus 3

Focus 3 is the terminal steering the e-bas system which features hopper low level sensor, various tramline systems, information about hectare, km/h, monitoring of fan speed, pre-emergence marker, seed rate adjustments. Focus 3 is not ISOBUS compatible.

IsoMatch Tellus GO+

The multifunctional one-screen terminal has been developed for fast and simple control of all ISOBUS implements, giving the farmer a ‘customer made’ experience as it suits all needs for plain and efficient handling of farming machinery and tasks. IsoMatch Tellus Go+ is the farmer’s first step into Precision Farming. With the easy to use application, IsoMatch GEOCONTROL, it is possible to boost efficiency and save time and costs. The application includes Manual Guidance, Section Control and Variable Rate.

IsoMatch Tellus PRO

IsoMatch Tellus PRO is the centre for connecting all ISOBUS machines and a platform for running precision farming applications. It offers everything a farmer needs to get the maximum out of his machines and crops, as well as cost savings in fertiliser, chemicals and seeds by using automatic section control and variable rate control. With the unique dual screen functionality it gives the farmer the opportunity to view and control two machines and processes simultaneously.

With this terminal you can work all the way as a PRO. The maximum working range for the task controller IsoMatch GEOCONTROL is increased from 2 km to maximum 10 km from the starting point. Thus even extremely big fields are handled in a full professional way. The new high brightness screen increases operator comfort. Visibility is increased during the day and dimmed to just a glowing display in dark conditions.

- The drill can be ordered with two different row spacings of 12.5cm or 25.0cm according to individual farming systems.

- The CX II coulters are clamped in staggered position over 2 rows by short and longer brackets.

- More clearance means different seed density and micro climate in the crop.

Choice of sowing distance

Sowing distance 12.5cm

- Best distribution for high seed rates

- Rows close quickly

- Reduced weed pressure

- Efficient use of nutrients, water and sun

Sowing distance 25cm

- Optimised micro climate reduces fungal infestation

- Less seeds needed per m² with new type of seeds (hybrid)

- Saving on water resources

- Reduced pulling force requested

- Better clearance in wet conditions

Caractéristiques techniques

Caractéristiques techniques

Télécharger la documentation| Type de machine | Satio 1050 F | Satio 1060 F | ||

|---|---|---|---|---|

| Châssis | porté repliable | porté repliable | ||

| Largeur de travail (m) | 5.0 | 6.0 | ||

| Largeur de transport (m) | 3.0 | 3.0 | ||

| Capacité de la trémie (l) | 1700 | 1700 | ||

| Trappe de vidange rapide | Standard | Standard | ||

| Capteur de niveau semence | Standard | Standard | ||

| Attelage supérieur | CAT II / CAT III | CAT II / CAT III | ||

| Attelage inférieur | CAT II / CAT III N / CAT III | CAT II / CAT III N / CAT III | ||

| Type de roue | 26x12.00 | 26x12.00 | ||

| Entraînement 1000 tr/min | Option | Option | ||

| Entraînement 540 tr/min | Option | Option | ||

| Entraînement de la turbine hydraulique | Standard | Standard | ||

| Doseur ELDOS à entraînement électrique | Standard (1) | Standard (1) | ||

| Radar de vitesse | Standard (1) | Standard (1) | ||

| Dosage petites graines | Standard | Standard | ||

| Electronique e-bas (Focus 3) | Standard | Standard | ||

| Electronique e-com (IsoMatch Tellus Pro/Tellus GO+) | Option | Option | ||

| Capteurs de contrôle du doseur | Standard | Standard | ||

| Réglage du débit de semences | Standard | Standard | ||

| Densité de semis (min. - max.) | 1 - 400kg/ha | 1 - 400kg/ha | ||

| Clapets de jalonnage | Option | Option | ||

| Fermeture électrique de demi-largeur | Option | Option | ||

| Traceurs de pré-levée | Option | Option | ||

| N° de CX-II en écartement 12,5 cm (nbre) | Standard (40) | Standard (48) | ||

| N° de CX-II en écartement 25 cm (nbre) | Standard (20) | Standard (24) | ||

| CX-II avec roue plombeuse | Standard | Standard | ||

| CX-II sans roue plombeuse avec disque galbé | Option | Option | ||

| Disque acier du CX-II Ø (mm) | 325 | 325 | ||

| Roue plombeuse Ø (mm) | 250 x 42 | 250 x 42 | ||

| Pression du CX-II (kg) | 5 - 50 | 5 - 50 | ||

| Réglage mécanique de la pression terrage des CX-II par manivelle | Standard | Standard | ||

| Réglage hydraulique de la pression d'enterrage des CX-II | Option | Option | ||

| Réglage centralisée par cales de la profondeur de semis | Standard | Standard | ||

| Herse recouvrement à dents en S (10 mm) | Option | Option | ||

| Efface-traces | Standard | Standard | ||

| Boîte à outils et kit d'étalonnage | Standard | Standard | ||

| Efface-traces hydr. repliable avec disque cranté | Option | Option | ||

| Plateforme avec marche-pieds de chargement | Option | Option | ||

| Feux de travail LED | Option | Option | ||

| Kit d'éclairage routier | Option | Option | ||

| Débit d'huile nécessaire turbine (l/min) | 30 | 30 | ||

| Puissance minimale requise (CV/kW) | 122/90 | 146/108 | ||

| Poids (kg) avec socs | 1370 - 2160 | 1450 - 2350 |

Caractéristiques techniques

Caractéristiques techniques

Télécharger la documentationModel |

Satio 1050 F |

Satio 1060 F |

Frame |

mounted foldable |

mounted foldable |

Working width (m) |

5.0 |

6.0 |

Transport width (m) |

3.0 |

3.0 |

Hopper capacity (l) |

1700 |

1700 |

ELDOS electric driven metering device (N°) |

Standard (1) |

Standard (1) |

N° of coulters 12.5cm distance (N°) |

40 |

48 |

N° of coulters 25.0cm distance (N°) |

20 |

24 |

Min. power requirement (HP/kW) |

122/90 |

146/108 |

Weight (kg) with coulters |

1370 - 2160 |

1450 - 2350 |